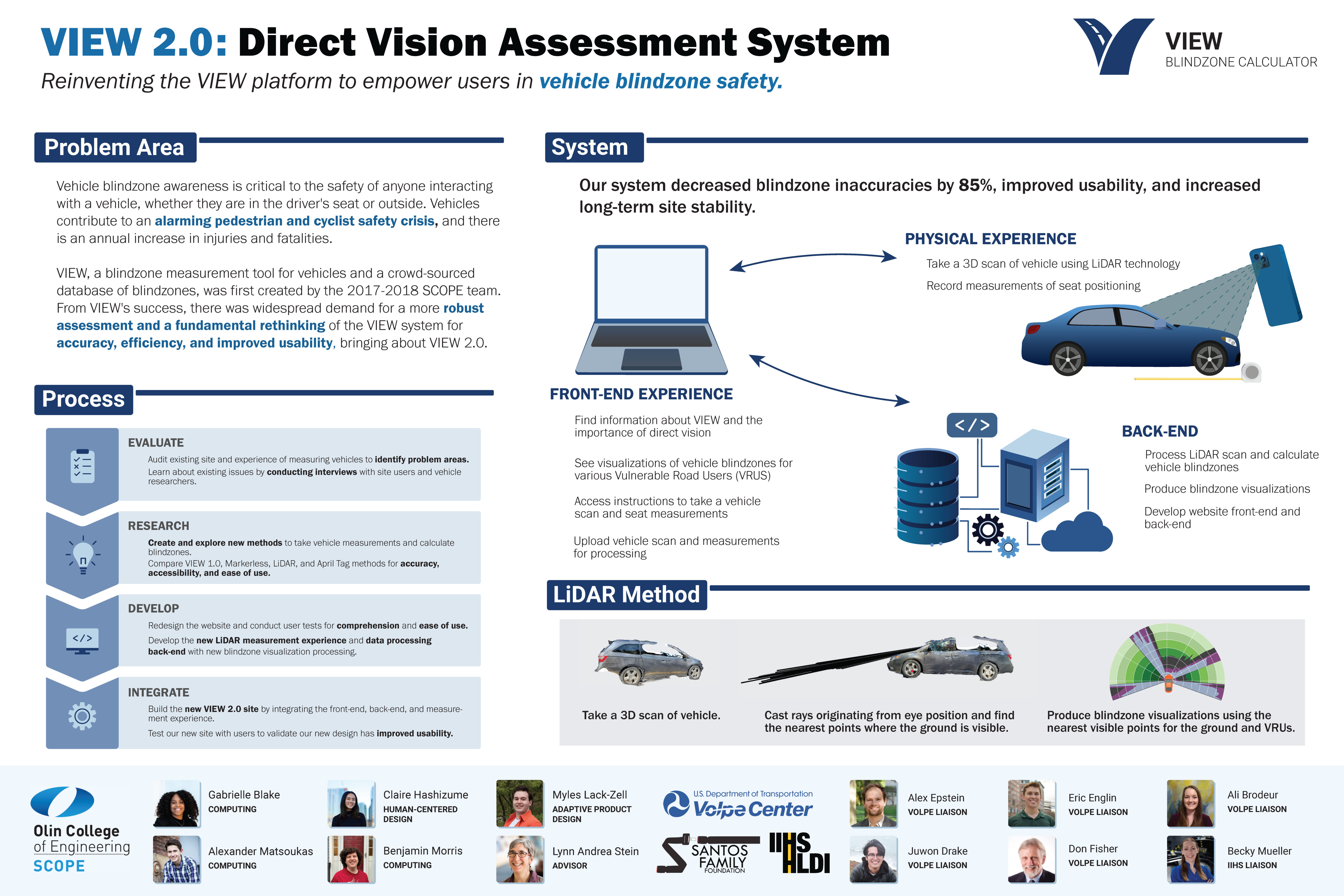

Developed as a year-long Senior Capstone Program in Engineering (SCOPE) project at Olin College of Engineering sponsored by the Santos Family Foundation in collaboration with the Volpe National Transportation Systems Center, Insurance Institute for Highway Safety (IIHS-HLDI), VIEW 2.0 is a direct vision assessment system that visualizes the blindzone of vehicles to increase awareness of vehicle safety issues and incorporate improvements to vehicle visibility into purchasing and design decisions. Our goals for the project were to: 1. Reimagine existing measurement technology to create an accurate and robust measurement method, 2. Design an intuitive user experience of the website and data collection so it supports everyday users, and 3. Increase long-term site stability.

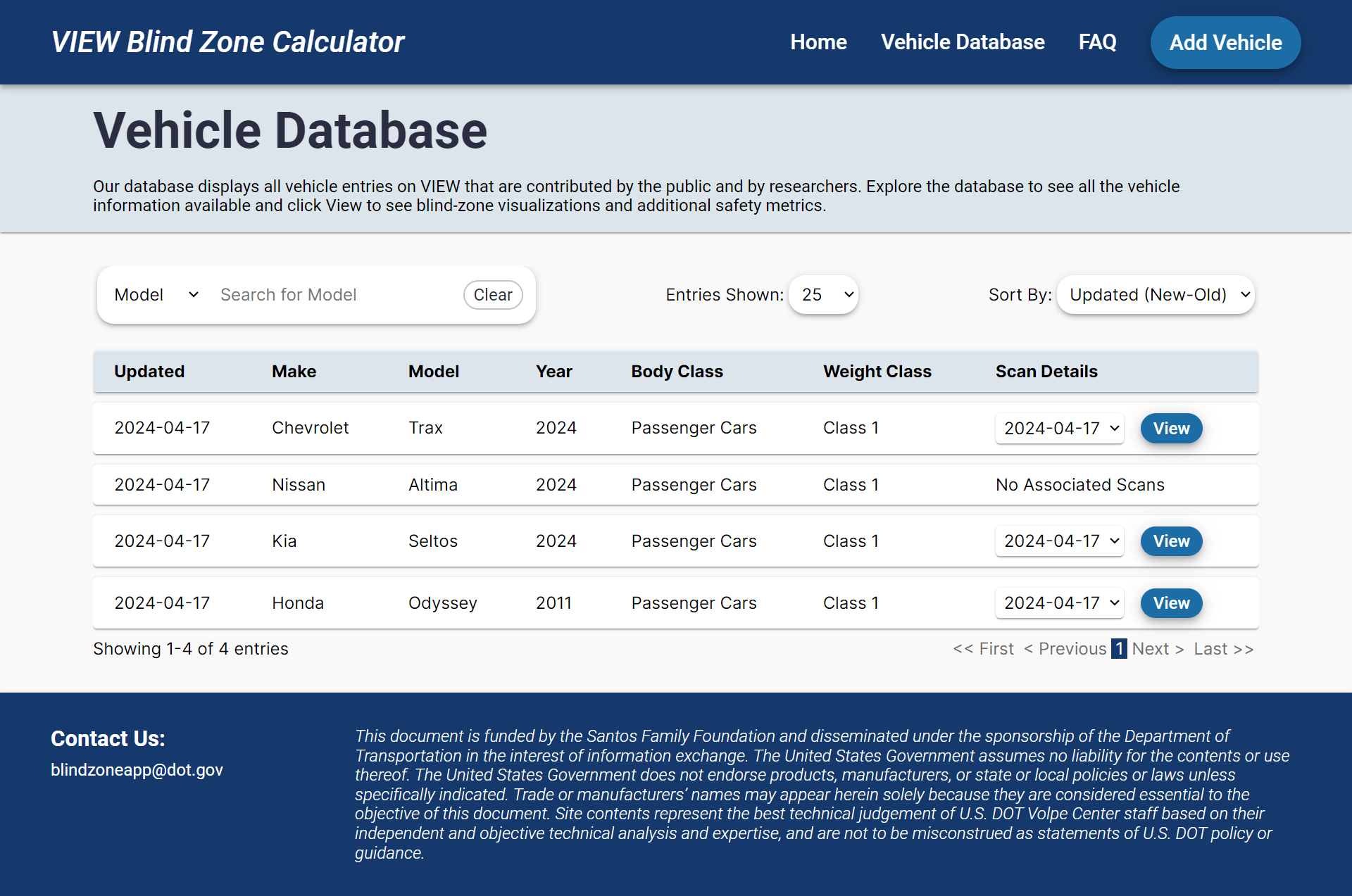

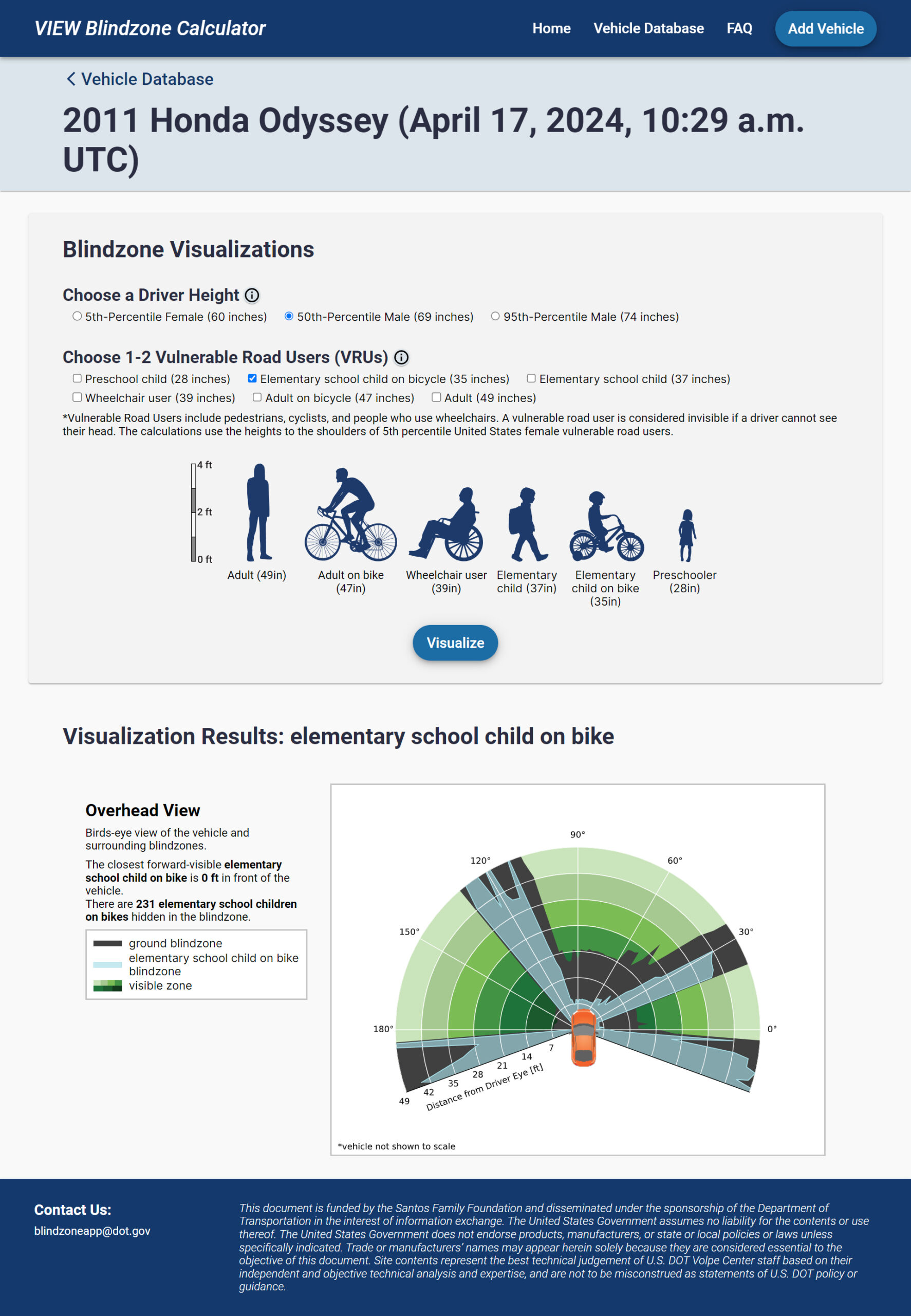

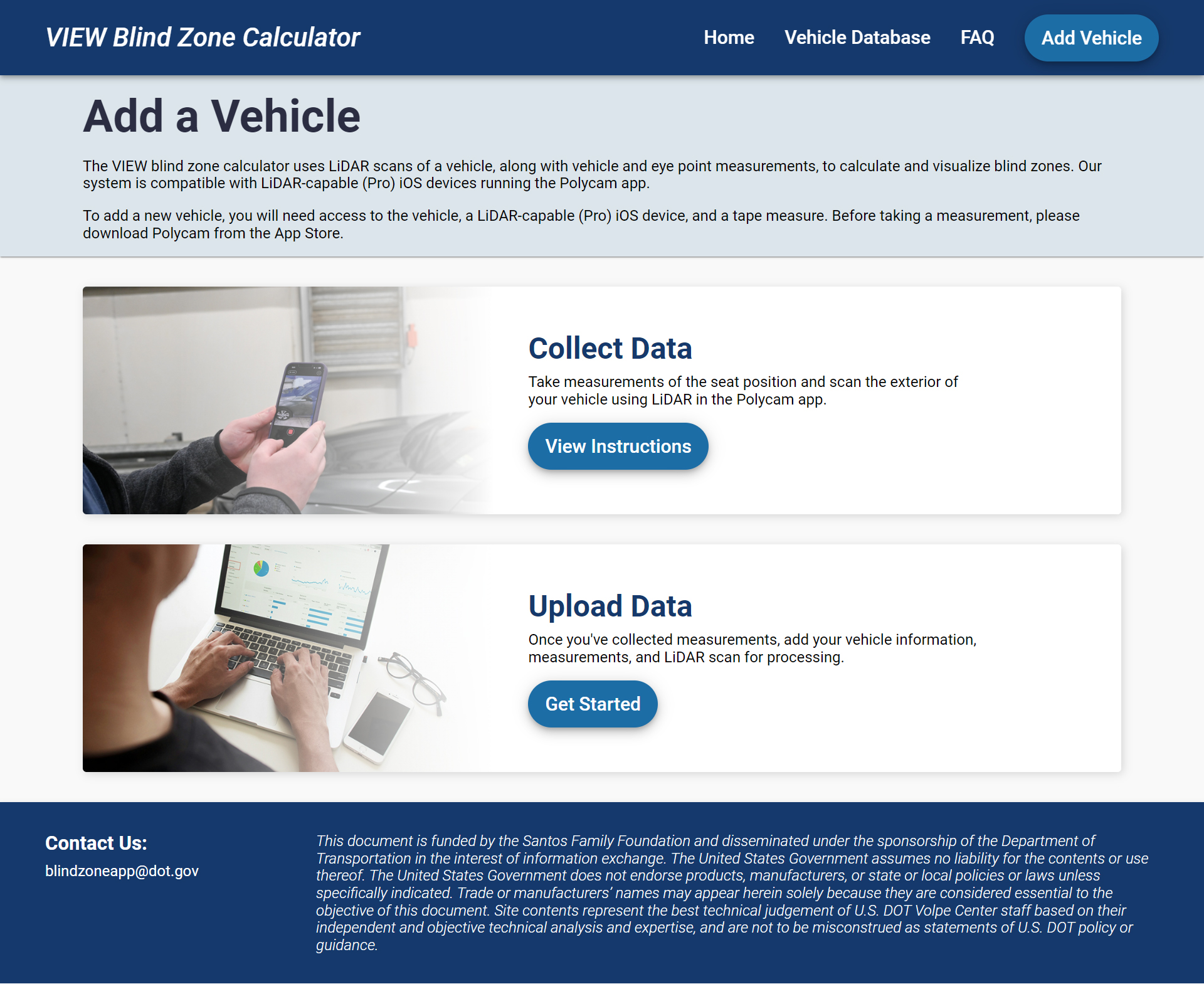

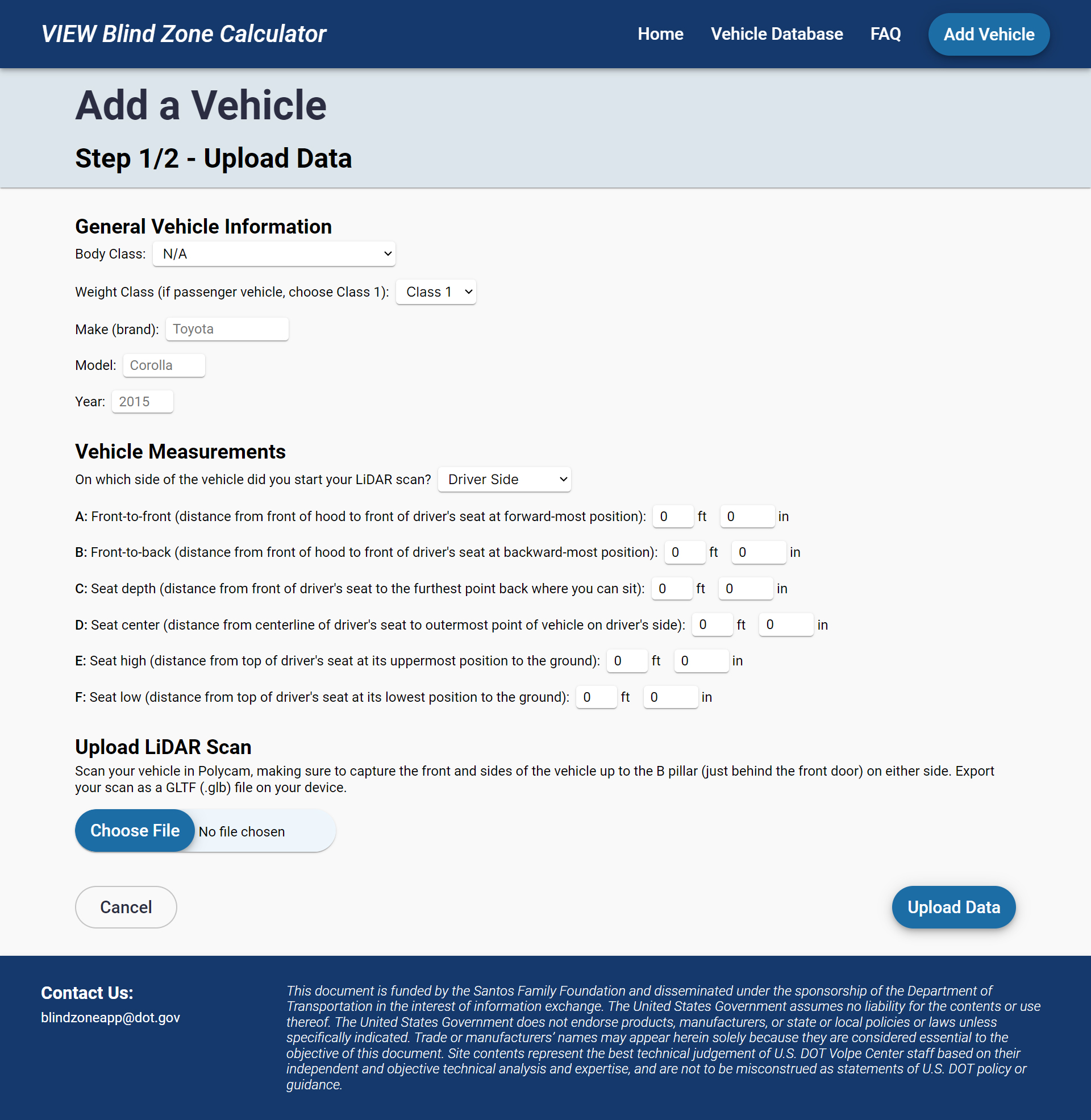

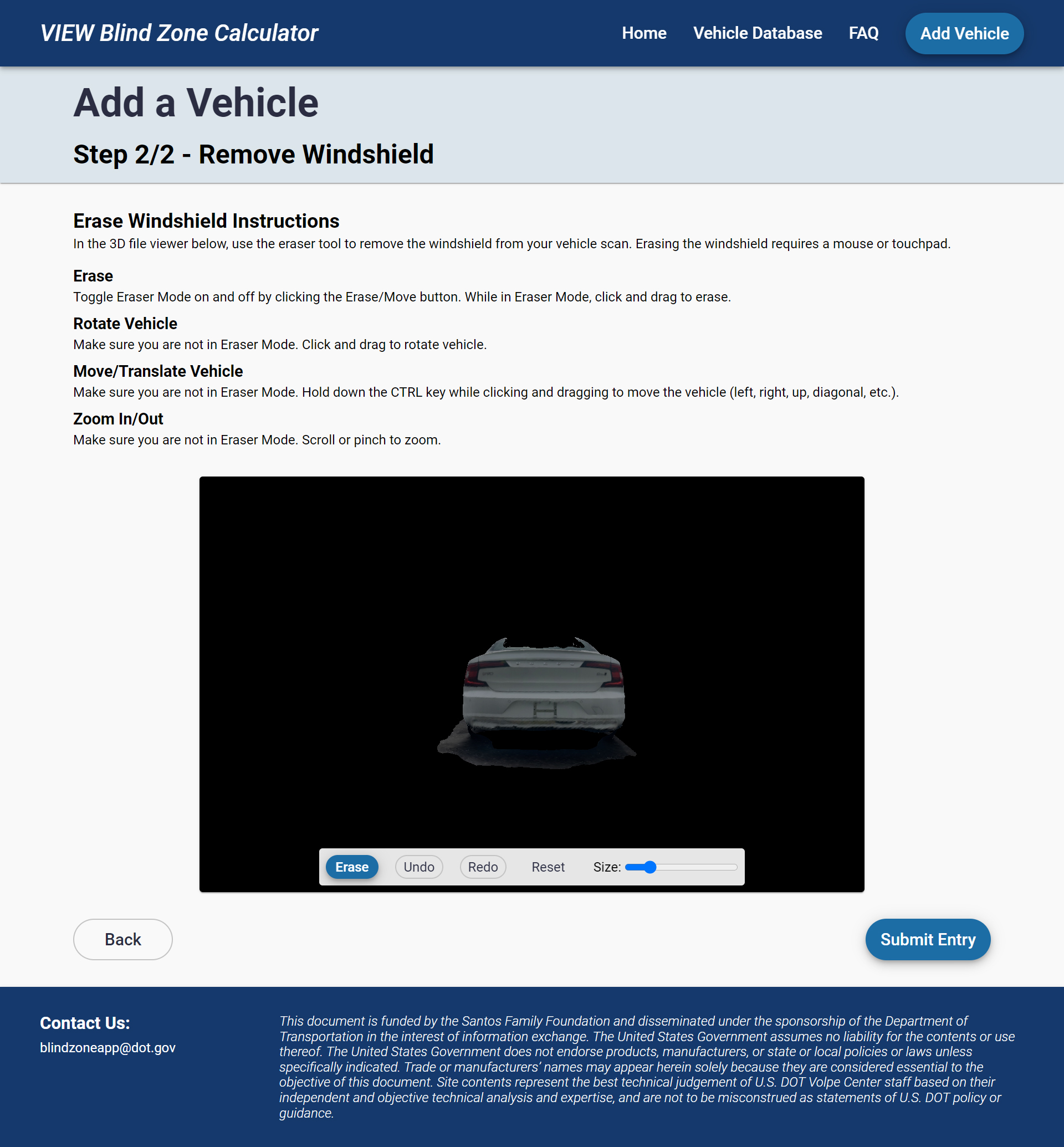

We identified different groups of users interacting with the VIEW ecosystem to understand the various needs and goals when using VIEW. We also started off the project by exploring various measurement methods for accuracy and usability: the two existing measurement methodologies, Panoramic and Markerless, developed by a 2017-2018 Olin College of Engineering SCOPE team and IIHS-HLDI, respectively, and two new methods we created, LiDAR and April tags. We ultimately decided to move forward and develop LiDAR to be integrated into the VIEW 2.0 site due to its accuracy for both passenger and larger vehicles and its reproducibility. Lastly, we started improving the user experience of VIEW by identifying areas for improvement with the website and conducting user testing on both VIEW 1.0 and our redesigned site throughout the year. We delivered a redesigned public website with guided measurement and data upload processes for both everyday users and industry specialists with robust, non-specialized measurement tools.

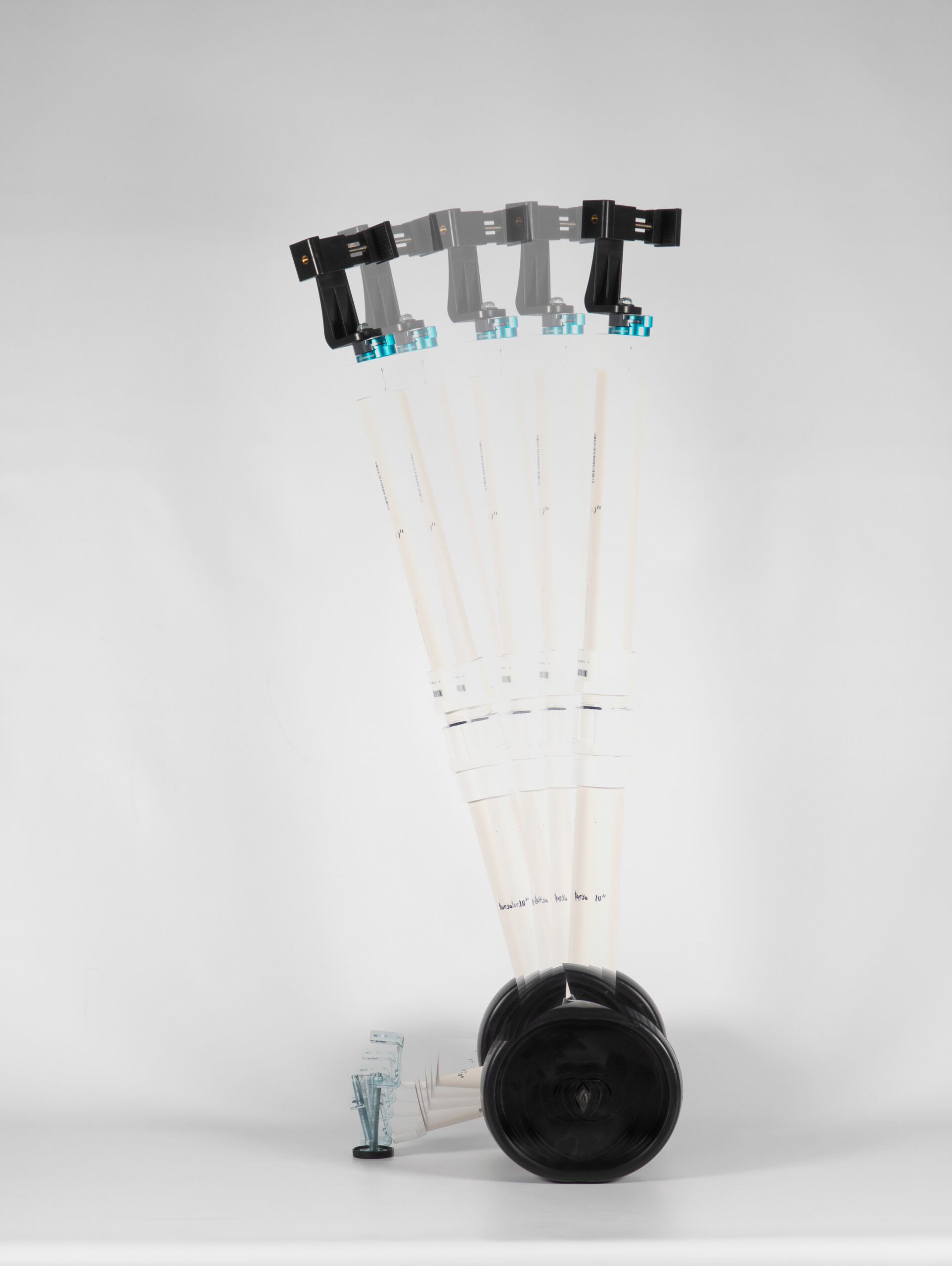

Within the team, I functioned as the budget manager, mechanical design lead, and as a UX designer/web developer. During the first half of the project, I designed, built, and documented a low-cost camera rig (LCR-1) as an alternative to the $1000+ custom camera rig built for IIHS-HLDI. LCR-1 is designed to be easily replicable using inexpensive hand tools and is made from PVC pipe and off-the-shelf parts to reduce costs. Step-by-step fabrication and assembly instructions, technical drawings, and a bill-of-materials allow individuals to build their own rigs for organizations to try out VIEW measurements.

For the second half of the project, I switched to developing the new website for the VIEW blindzone calculator based on the team’s Figma mockups. The frontend of the website was initially built using TeleportHQ before working directly with HTML/CSS to fix bugs, replace components, and build out views for more advanced features. We based the website design on Material Design 2, albeit with some changes, due its relative ease of implementation and the fact that the design system’s cognitive accessibility was well-regarded despite being a flat interface. Colors on the site were chosen to fit with Volpe’s branding and meet WCAG contrast guidelines.